TT Technique

Each unique Curved Frets™ pattern is designed to specifications derived from our exacting Dynamic Intonation™ process.

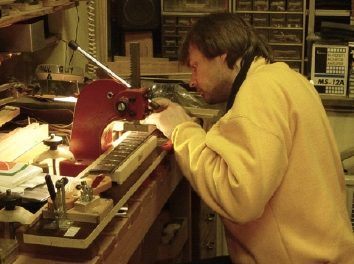

This is Anders Thidell doing the Dynamic Intonation boogie (actually it's more of a slow blues).

Every note is adjusted and fine-adjusted (and then re-checked and re-adjusted dozens of times) until it produces the required pitch, measured both by ear and with a sensitive strobe tuner. This is repeated with new strings until we have unequivocal and stable results.

This requires enormous patience and concentration, which fortunately Anders has lots of. (When he is focused on a job, you can speak to him and he won't even hear you - not the first time, anyway !)

Measuring up the fret positions is also a job for Job. This whole process has to be repeated for every different temperament and/or scale length.

The co-ordinates are programmed into the CNC (computer-controlled) machinery which routs our fret slots to extremely fine tolerances.

The result looks like this:

Fret models are made by hand to fit precisely in each fret slot (here one of Anders' more extreme efforts!). These are used to make the casting moulds for our Curved Frets™.

Curved Frets™ are precision cast in silicon bronze, chosen for its low coefficient of friction and high resistance to wear.

They are press-fitted under precisely controlled pressure.

The special silicon bronze alloy is a close relative of the copper/nickel alloy used in regular fretwire, but with no nickel in the formula. (Good news for players allergic to nickel.) The copper content makes them sound just like regular frets, unlike some even harder materials which can contribute an unwanted “clangy” brightness to the sound.

If you do manage to wear them out, or damage one or more , you can get replacements, or a whole new set, from us at a nominal cost.

After installing and trimming the frets, we use a metal shield to protect the fingerboard while we dress and polish them.

©Paul Guy/True Temperament AB, 2006

Patent Pending